Combi gas oven 40 places Baron OPBGT202 with boiler

Available Options

Price with options:

Price with options:

Description

Combi gas oven 40 places Baron OPBGT202 with boiler

Optimus series features with touch control

- Made by BARON Italy

- Automatic Cooking System AC (Automatic Cooking) with international recipes and photo of the final dish

- Manual mode with 3 cooking modes: convection (air) from 30°C to 300°C, steam from 30°C to 130°C and combination (Combi) from 30°C to 300°C

- Programmable cooking processes with the possibility of automatic sequences (up to 15 cycles). Each program accepts its own name, photo and information about the recipe

- CLIMA® system, for automatic measurement and control of humidity levels in the chamber

- FastDry® system for rapid removal of humidity from the chamber

- Automatic washing system with integrated detergent container and automatic dispenser

- Automatic reversal - Perfect air distribution in the chamber with automatic reversal of the fan direction >

- Manual washing system with externally connected shower (optional)

Operation

- 7'' high-resolution LCD Touch Screen >

- Touch screen that can be adjusted according to the user's needs to bring to the fore the most used programs

- Automatic Cooking System with immediate activation, AC - One Touch

- Recipe organization in folders with preview and distinctive name

- Smart recognition of recipes in subfolders

- SCROLLER PLUS control with scrolling and pressing capabilities to indicate options

- Self-diagnosis and operation check procedure, before using the equipment with description and audible warnings for each activation cause

- Automatic washing system (LM) with external detergent tank and automatic dispenser - supplied with 1 DL010 cleaning liquid tank - 990 gr

Equipment

- Automatic reversal (perfect air distribution in the chamber with automatic reversal of the fan direction)

- Automatic parallel control of room and core temperature, DELTA T system

- Automatically adjustable steam condensation

- Easy access to programmable settings, so that the device can be configured from the user menu

- Programmable postponement / delay of the cooking process

- Possibility of selecting 6 air speeds. The first 3 speeds activate an automatic reduction in thermal power

- For special cooking methods you can use intermittent air flow

- Core temperature control with 4-point sensor

- Connection of the core sensor to a socket outside the chamber with the possibility of quickly adjusting the thin "needle" sensor for vacuum cooking or for very small pieces

- USB connection for storing HACCP data, for software upgrades and copying/transferring cooking recipes

- IPX5 waterproof protection (against water spray)

- Door with double heat-treated glass that reflects heat inwards and with an air gap between them for less radiation towards the operator and greater efficiency

- The inner glass opens with a hinge for easier cleaning

Special technical characteristics of the model OPBGT202 with Boiler

- Capacity: 20 x 2/1GN - 40 x 1/1GN

- Height / distance between pans: 63 mm

- Heat Production: Gas Fuel

- Steam Production: Boiler - Boiler

- Power Supply: AC230V 50Hz

- Electrical Power: 1.8kW

- Thermal Power: 80kW / 68800Kcal

Included:

- Automatic LM cleaning system - supplied with 1 DL010 cleaning fluid container - 990 gr.

- Multi-point core sensor. Ø 3 mm

- CALOUT descaling system (for models with boiler)

- USB connection

- Trolley [code: KKS202]

Accessories that can only be requested when ordering (with extra charge):

- Ethernet network connection [code: SN]

- Configuration for connection to the hood[code: NPK]

- Hood with air-cooled condenser, dimensions 129.3x114.7x30cm, power 0.3kw 230V [code: NKC202]

Accessories that can also be installed after purchase (extra charge):

- Core sensor for large items. Nail length 180mm Ø 3 mm [code: KSC180]

- Needle-type core sensor. Ø 1 mm [code: KSA001]

- Multi-measurement system, 2 multi-point core sensors. Ø 3 mm [code: KSM002]

- Hand shower, accessories and connectors [code: ICLD]

- Grease filter [code: NFX02]

- Marine feet set - with flanges for installation in ship galleys [code: NFP24]

Special accessories (extra charge):

- Trolley for 20 x 2/1GN - 40 x 1/1GN, 63mm level distance, with residue collection tray. Dimensions 69.4x83.5x171cm. [code: KKS202]

- Trolley for 15 x 2/1GN - 30 x 1/1GN, level distance 83mm, with residue collection tray. Dimensions 69.4x83.5x171cm. [code: KKS202S]

- Maintenance chamber for 20 x 2/1GN - 40 x 1/1GN, dimensions 111x108x195cm, power 7.5kW 400V [code: MFP40E]

- Maintenance chamber for 20 x 2/1GN - 40 x 1/1GN, with front - back door (passthrough), dimensions 111x108x195cm, power 7.5kW 400V [code: MFP42E]

- Regeneration chamber for 20 x 2/1GN - 40 x 1/1GN, dimensions 111x108x195cm, power 23kW 400V [code: RFP40E]

-

Regeneration chamber for 20 x 2/1GN - 40 x 1/1GN, with front - back door (passthrough), dimensions 111x108x195cm, power 23kW 400V [code: RFP42E]

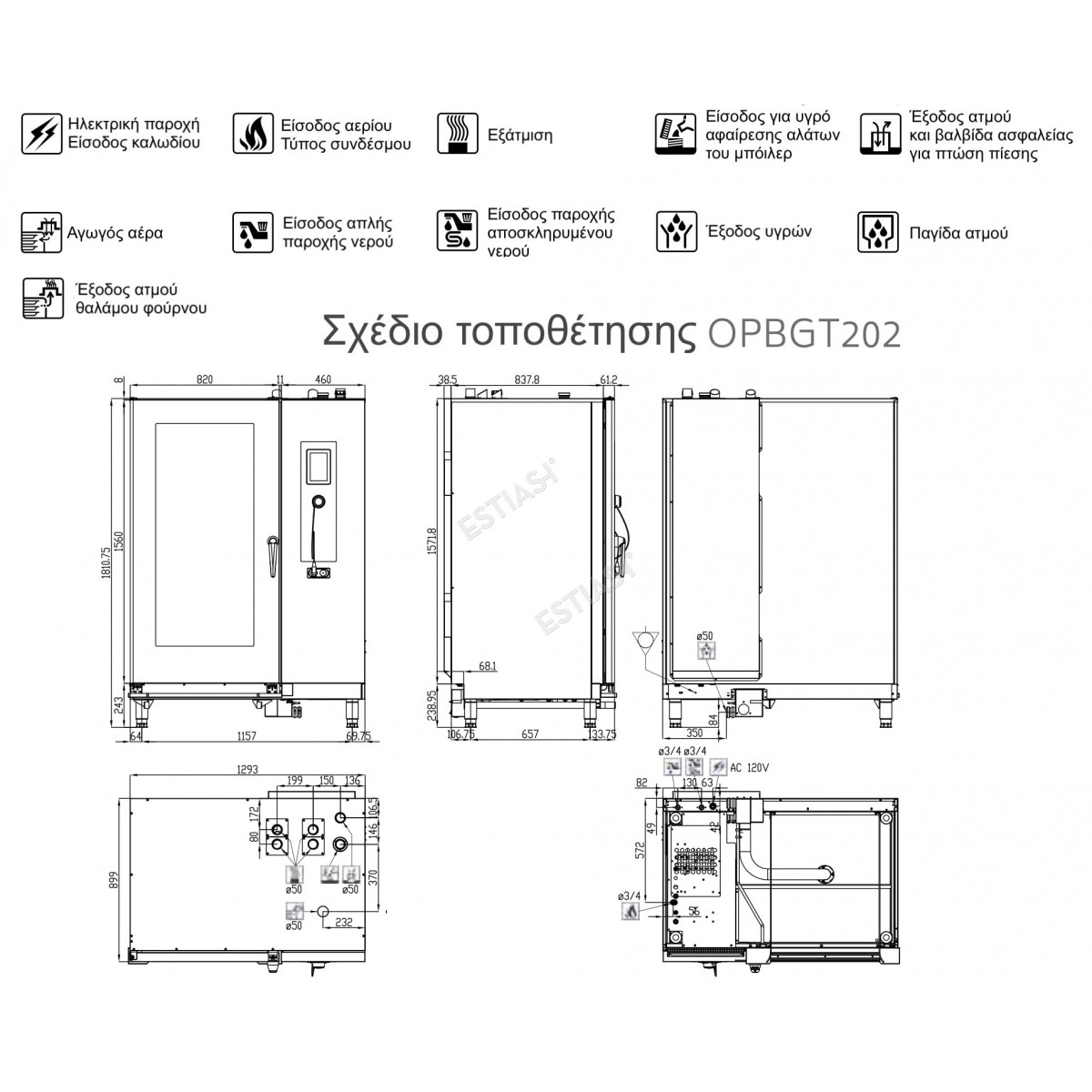

Specifications

| Dimensions | |

| External length (cm) | 129 |

| External depth | 89.5 |

| External height (cm) | 181 |

| Capacity | |

| Number of trays | 40 |

| Other | |

| Brand: | BARON |

| Weight | 465.00kg |

Ελληνικά

Ελληνικά  English

English